Finding the edge with Richard Allen

It’s often said that ‘Necessity is the mother of invention’. The construction method I’ve now branded as EcoBunker is no different, stemming from a need to reduce the onerous burden of golf bunker maintenance. How did this idea turn into a product that has now been built on over 300 golf courses, in 33 different countries. I had been interested in golf course design and construction for many years, including an interesting and rewarding term as a Chairman of Greens in the mid 1990’s, during which I designed and gained planning approval for a new golf hole which ultimately became one of the most popular on the course. Several years later, playing regularly at one of South Wales’ best courses (A Colt Renovation), I noticed that the bunkers were being rebuilt into very regular and utilitarian shapes. The quality of the workmanship was outstanding, but to my eye the new designs did not suit the course, which was over 100 years old. When I queried why this approach was being taken, I was informed that the old style bunkers, with raised sand faces and irregular shapes with varying height edges, were too costly to maintain. The new bunkers would allegedly reduce edging work and grass cutting could now be done with ride on mowers instead of hand strimming the steeper banks.

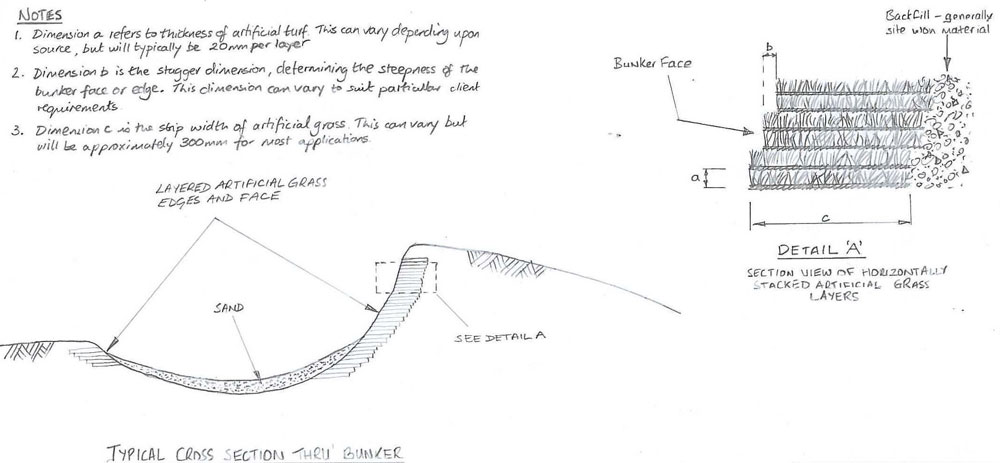

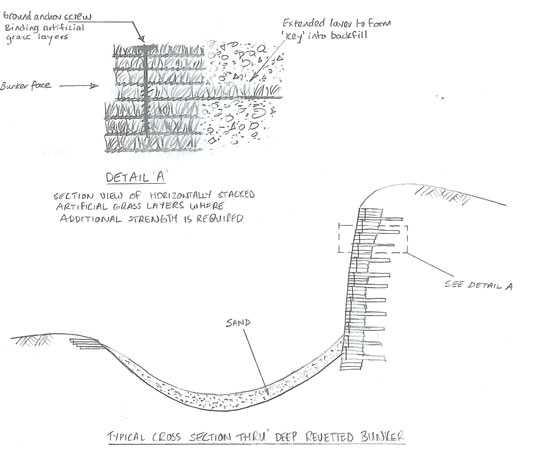

Personally I thought this was a huge shame, and I had many discussions with a friend of mine, golf course architect Jonathan Gaunt. Jonathan stated with regret that this was not unusual, a fact later confirmed by Adam Lawrence, the editor of Golf Course Architecture Magazine. During several conversations Adam and I agreed that it would be great if some golf courses could be ‘listed’ like historic buildings, although we both admitted this was highly unlikely to ever happen. Perhaps I was overly sensitive, but I emerged from this experience determined to find a way of building ‘beautiful’ bunkers in a more maintainable manner. I then began to notice that links courses too had especially difficult problems maintaining their revetted style bunkers as I pondered ideas and solutions. About a year later came the ‘light bulb moment’ – or more accurately the ‘car headlight moment’. I was sitting alone in my car ready to drive home from a late meeting at my golf club. Turning on the headlights, the beam hit a roll of used astroturf and lit up the layers of artificial grass. It looked to me like the layers of turf in a revetted bunker face. Over the next few weeks I did some research: I knew from my work in development that there was a lot of this waste astroturf being dumped at great cost into landfill, and I found out that the material was not biodegradeable, making it highly resilient and durable. I made a few sketch designs and then considered my next action. It was never going to be an easy task to persuade a golf course to re-build a bunker using my idea of layering synthetic sand filled grass and finally I decided to explain my design to a good friend of mine who had recently become the Chairman of the Greens at my local golf club. To take things forward I showed him the rolls I had seen, and then explained to him what I had learned previously about the maintenance problems with bunker face and edges, and that I thought there could be real potential for a resilient solution. He was impressed and relieved. The club had run out of ideas on what to do with the unwanted pile of astroturf, after overestimating the amount needed for their only proposed use: surfacing pathways. Then the hard work began: Putting the Intellectual Protection in place (my established connections with WRAP helped release valuable funding for this expensive process), building a model, working out how to cut the turf efficiently and not least, persuading other golf clubs to trial this highly innovative concept.

Contact us about EcoBunker distribution in your territory

Problem Solving by Invention and Innovation

Problem Solving by Invention and Innovation

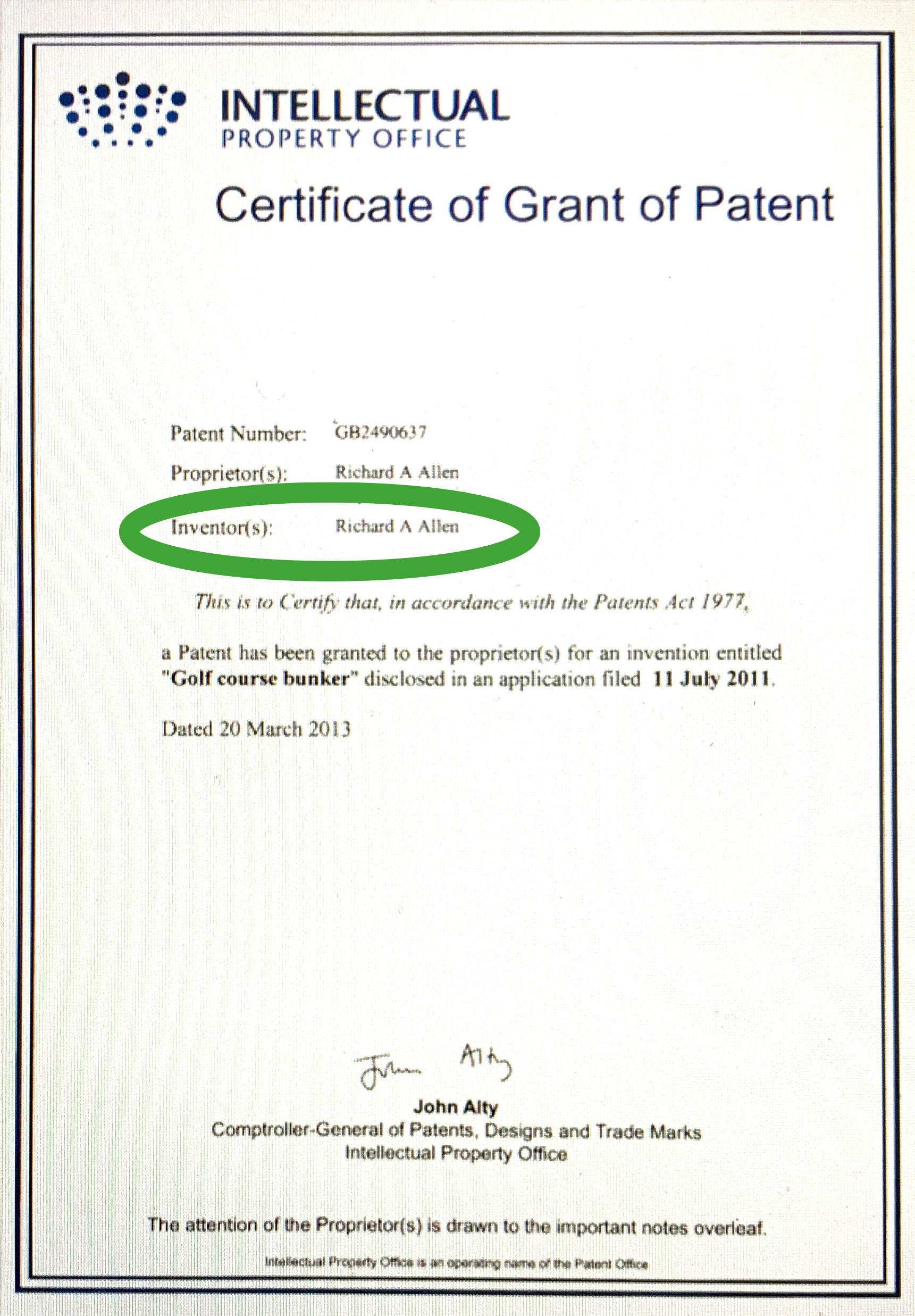

At EcoBunker Ltd we are passionate about great design. Whether it is civil or structural design undertaken by our experienced engineer and CEO, Richard Allen, or a beautiful bunker crafted from architects plans by our lead shaper, Llewellyn Matthews, we care deeply about the construction and aesthetics of our projects. Richard was the inventor of the synthetic turf construction method and was behind all the innovative technical work at Envirosports Ltd. When a lack of investment at that company effectively put a brake on innovation and invention, Richard, Llewellyn and all the technical and sales staff set up EcoBunker Ltd, and embarked upon developing better products capable of solving more challenges. The range of advances are evidenced by products like EcoBunker Advanced, Aquaedge and several other patent applications and independently developed know-how.

Pioneers

We are committed to continual improvement and we welcome the opportunity to solve new challenges. As a result we have been the first to influence the way that features (not only bunker edges) on the golf course are constructed. Below we include a selection of the ‘FIRSTS’ that can be directly attributed to EcoBunker Ltd and their team.

CMS (Cement Modified Soil) Hybrid wall construction: Improved strength, sustainability, safety and cost saving.

Aquaedge, for easy maintenance, razor sharp water margins.

Sub soil irrigation of bunker edges by adaptation of patented technology from the landscaping sector.

Double and Triple stacking to create more authentic links style bunker revetting aesthetic.

A range of wall surface finishes including painted options and hydroseeding to accelerate the naturalisation process.

EcoEdge; The first zero maintenance bunker edge.

EcoTec; The first bunker liner to tick ALL the boxes.

Intellectual Property Rights

The list below provides a list of the current patents (granted & pending). Patents (or in the USA Utility Patents) generally relate to the ‘mechanics’ of the invention and usually offer the strongest form of protection once granted.

| Description | Inventor | Own | Status | Comments |

|---|---|---|---|---|

| Ecotec, a geotextile membrane comprised of a matrix of interlocked polymeric filaments with a variable density through the profile | Allen | 100% | Pending | Preliminary Examinations Complete |

| Method of Constructing walls using a plurality of predominantly horizontal layers of artificial grass | Allen | 50% | Granted | GB2490637A & EP2590717 |